A Hope Valley heavy industrial company has been fined $350,000 in the Rockingham Magistrates Court after a young apprentice suffered serious burns while welding.

The 16-year-old, who was working at National Steel, was instructed to perform welding work in a welding bay in July 2021.

He was wearing an undershirt, work shirt and hi-vis hoodie, along with a welding helmet, respirator and welding gloves.

The teenager then replaced the hoodie with a with a hi-vis tradie jacket, and during his next weld he felt heat on his arm.

When he removed his helmet, he discovered that his jacket, shirt and undershirt were on fire.

The apprentice then lay down in a puddle of water on the ground to extinguish the flames but by that time he had suffered serious burns to his abdomen, chest and hand requiring two surgeries with skin grafts, long term pain and an infection, and post-traumatic stress disorder.

National Steel failed to notify WorkSafe of the injury which was required under the laws at the time.

WorkSafe Commissioner Sally North said the case sends a strong message to workplaces in which welding is carried out to ensure workers use all appropriate personal protective equipment and that young and new workers are provided with training and supervision in all workplaces.

“The 16-year-old involved in this incident should have been closely supervised given his young age and minimal experience and should have been provided with fire-retardant clothing and instructed to wear a welding apron,” Ms North said.

“In addition, he did not receive a formal induction that included instruction on workplace safety, nor was he given any safety induction documents.

“He was not issued with company-supplied protective clothing, as his employment began after the annual allocation of long-sleeved fire-retardant cotton work shirts.

“No senior staff member was constantly supervising the apprentice at the time of this incident. His supervisor walked past him a number of times but did not instruct him to wear an apron despite being aware of the risks of hot work such as welding.

“The young man’s clothing had previously caught fire and he was subsequently given a leather welding apron, but no policy was enforced that required workers to always wear the apron or a welding jacket while welding. Not all welders at the workplace wore aprons when welding.

“A job safety analysis had been prepared for welding that specified the protective equipment required, but this was not enforced.

“It’s not enough to simply have safety rules – they need to be implemented."

Stolen Ford Mustang linked to southern suburbs incidents

Stolen Ford Mustang linked to southern suburbs incidents

Baldivis: Truck fire forces closure of Kwinana Freeway

Baldivis: Truck fire forces closure of Kwinana Freeway

Concerns for missing Baldivis girl

Concerns for missing Baldivis girl

MARC leisure pool, pirate playground to close for several weeks due to maintenance works

MARC leisure pool, pirate playground to close for several weeks due to maintenance works

Petition launched to change new Eastern Foreshore playground due to safety concerns

Petition launched to change new Eastern Foreshore playground due to safety concerns

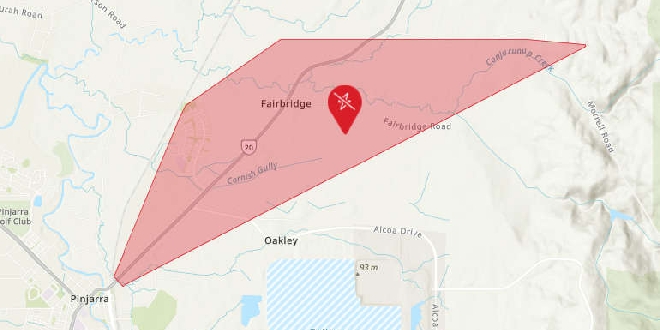

Parts of Pinjarra, Fairbridge without power

Parts of Pinjarra, Fairbridge without power

Bouvard scrub fire deemed suspicious

Bouvard scrub fire deemed suspicious

Peel Thunder crush Perth in WAFLW season opener

Peel Thunder crush Perth in WAFLW season opener

Baldivis man charged after AFP seize haul of cigarettes, vapes, $2.6M cash

Baldivis man charged after AFP seize haul of cigarettes, vapes, $2.6M cash