Rio Tinto will invest $215 million into a new research and development facility in East Rockingham in a bid to support reducing emissions in the steel industry.

The facility, in the Rockingham Strategic Industrial Area, will trial Rio Tinto's BioIron process, which uses raw biomass like wheat straw and canola stalks to turn Pilbara iron ore into metallic iron, creating a low-carbon iron for steelmaking.

The process eliminates the need of coking coal in the steelmaking process and could result in a reduction in carbon dioxide emissions from steelmaking of up to 95 per cent.

The BioIron facility is expected to create around 60 construction jobs and support about 30 full-time employees.

Fabrication of equipment for the facility will begin this year, with commissioning expected in 2026.

“As one of the world’s largest iron ore producers, it just makes sense for WA to lead the world when it comes to low-emission steelmaking," Premier Roger Cook said.

“Our plan to turn WA into a renewable energy powerhouse opens up massive economic opportunities for the future, like producing low-emission steel right here at home."

Rio Tinto Chief Executive Iron Ore Simon Trott said the world needs low-carbon steel to reach net zero.

"We are working to make this a reality by finding better ways to turn our Pilbara ores into steel," Mr Trott said.

“BioIron is a world-first technology that has the potential to play a significant role in a low-carbon steel future.

“This research and development facility will further test the BioIron process, showcase Western Australian innovation capability, and further demonstrates Rio Tinto’s commitment to supporting and enabling the decarbonisation of the steel industry.”

Stolen Ford Mustang linked to southern suburbs incidents

Stolen Ford Mustang linked to southern suburbs incidents

Baldivis: Truck fire forces closure of Kwinana Freeway

Baldivis: Truck fire forces closure of Kwinana Freeway

Concerns for missing Baldivis girl

Concerns for missing Baldivis girl

MARC leisure pool, pirate playground to close for several weeks due to maintenance works

MARC leisure pool, pirate playground to close for several weeks due to maintenance works

Petition launched to change new Eastern Foreshore playground due to safety concerns

Petition launched to change new Eastern Foreshore playground due to safety concerns

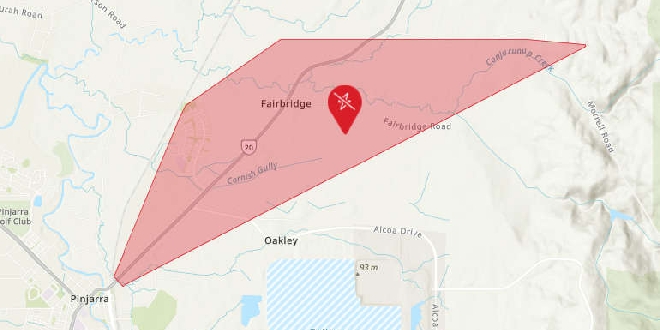

Parts of Pinjarra, Fairbridge without power

Parts of Pinjarra, Fairbridge without power

Bouvard scrub fire deemed suspicious

Bouvard scrub fire deemed suspicious

Peel Thunder crush Perth in WAFLW season opener

Peel Thunder crush Perth in WAFLW season opener

Baldivis man charged after AFP seize haul of cigarettes, vapes, $2.6M cash

Baldivis man charged after AFP seize haul of cigarettes, vapes, $2.6M cash